VERSATILE FILTER PRESS

A versatile system with increased filtration capacity and an innovative Czech plate to optimize the process.

or download the brochure

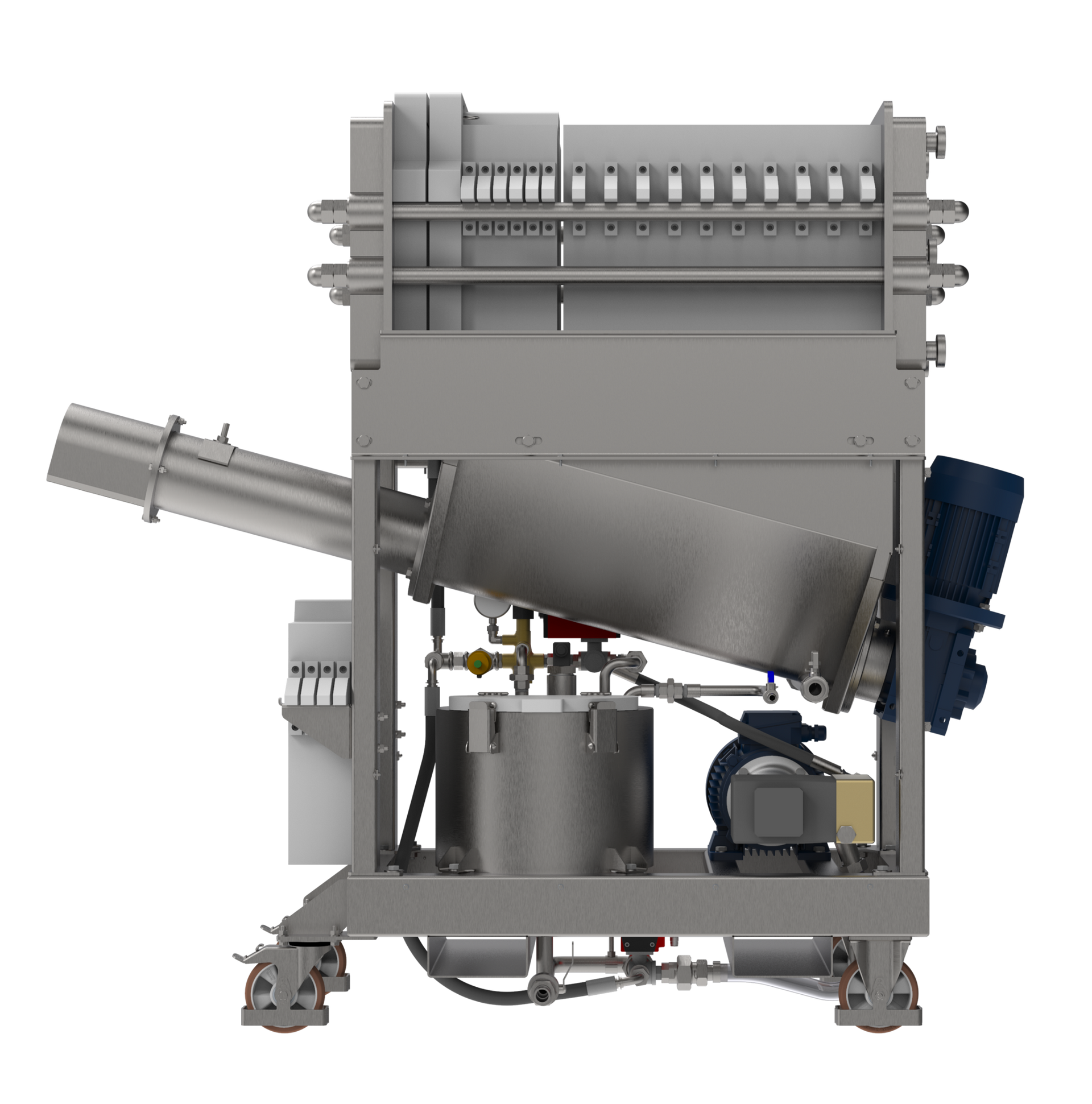

The Exoos Pratico is a compact version of the Exoos Massimo industrial filter press. It's designed for mills and oil mills processing smaller volumes of high-quality oil, where a large system wouldn't be justified, but filtration quality remains a priority.

Despite its smaller size, the Exoos Pratico retains all the optional features and offers a simple, modular, and economical solution. It guarantees an efficient, clean, and rapid process: the practical answer to everyday filtration needs.

Forehead

1

Precoat/Slurry Tank

For the formation of the initial panel and the dosage of adjuvants during filtration.

2

Filtered oil tank

The filtered oil is collected in a tank, to then be stored or bottled.

3

Electrical panel

All electrical wiring is collected here.

4

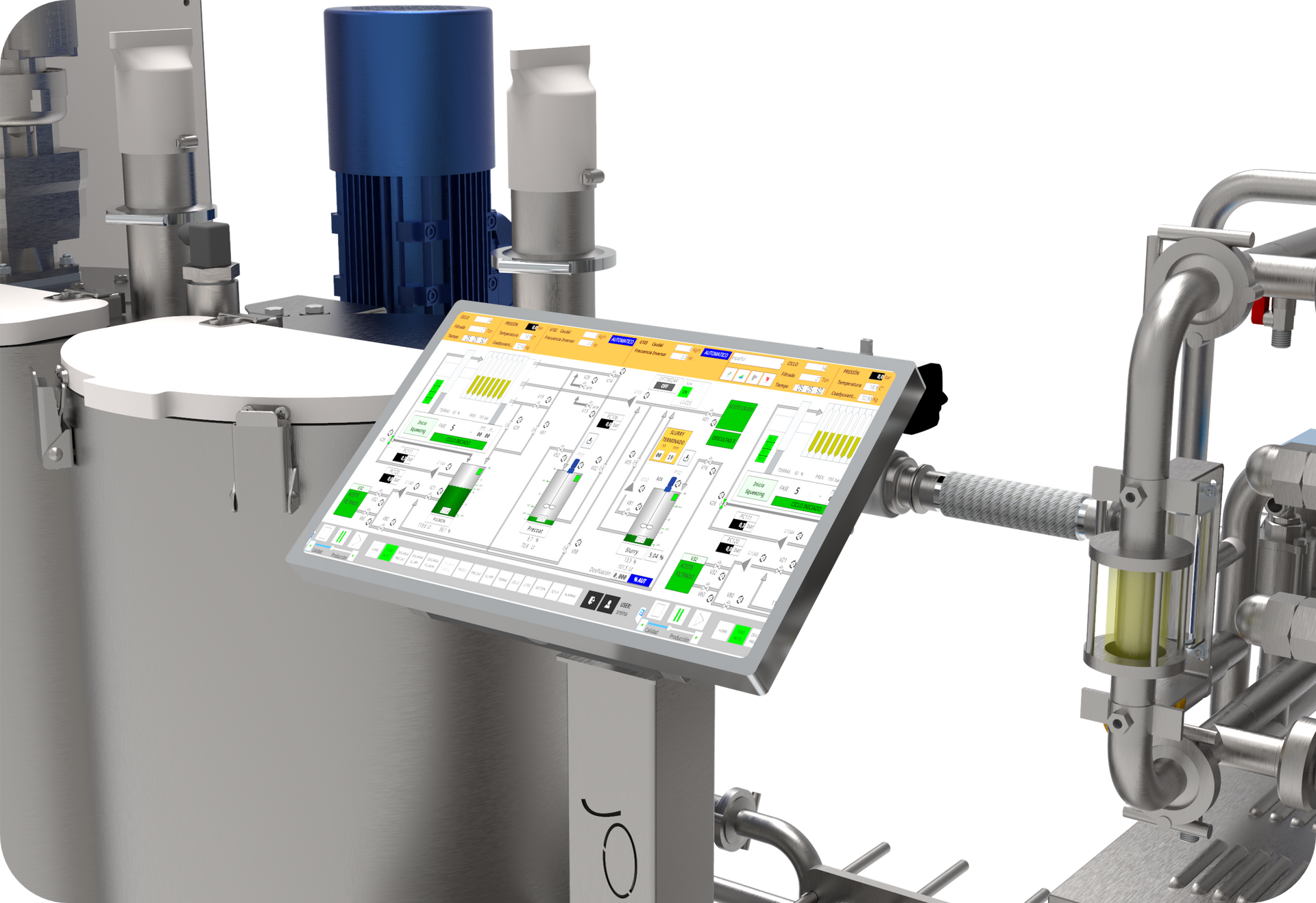

Touch control panel

From this control panel it is possible to manage all the parameters of the machine and the filtration cycle.

5

Filter press block

In a new super compact design, the new filter press block includes a new set of filter plates.

6

Oil inlet

DIN quick coupling also for flexible pipes.

Retro

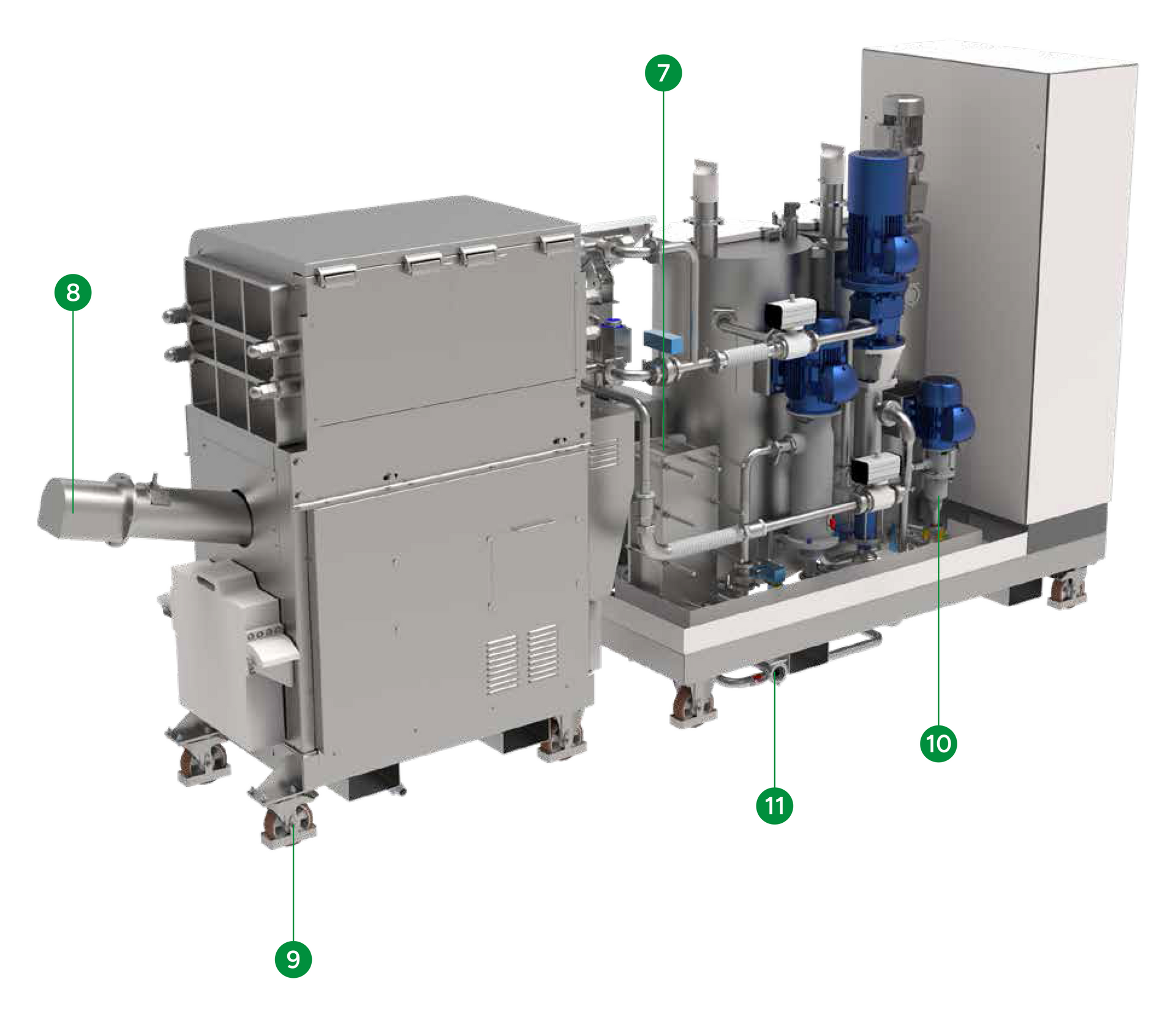

7

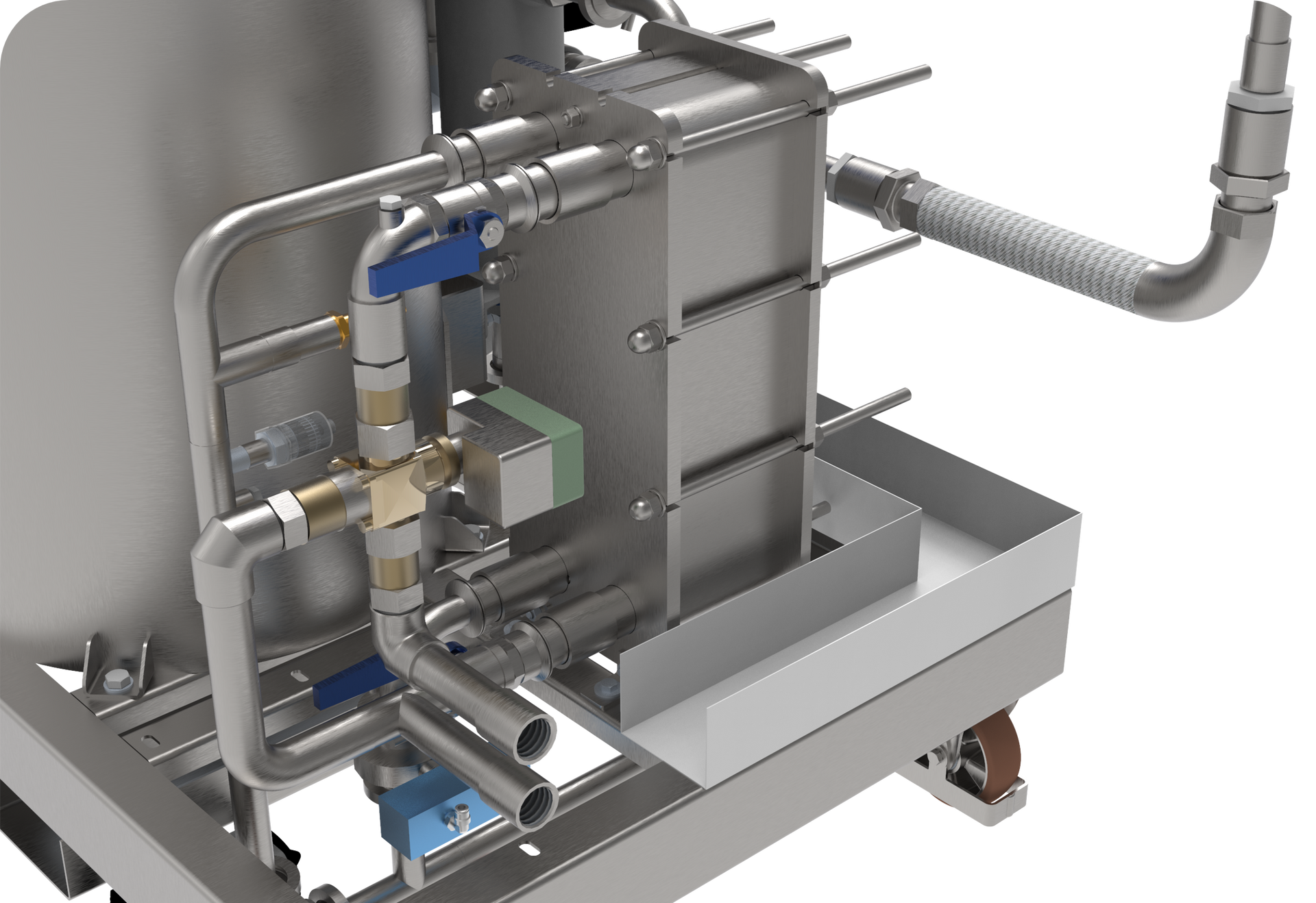

Heat exchanger

The use of the heat exchanger allows, if desired, to filter the oil at the ideal temperature, always guaranteeing the maximum quality of the filtered extra virgin olive oil.

8

Cochlea

The exhausted panels are collected in a hopper equipped with an auger, allowing them to be accumulated in an external bin.

9

Wheels

The entire system is equipped with wheels with brakes, for easy movement of the system.

10

Single-speed pump

The exoos system is equipped with 3 single-screw pumps, without the need for external pumps.

11

Filtered oil outlet

DIN quick coupling also for flexible pipes.

Some of the main advantages

The Exoos range of filter presses offers advanced and compact filtration solutions, combining efficiency and automation with quality and cleanliness in a single system.

Effective and efficient filtration even on freshly extracted extra virgin olive oils, with immediate product stabilization and maintenance of quality characteristics.

Drastically reduced oil losses up to 10 times lower than traditional systems, ‹ 0.5%, or less than 0.5 kg per 100 kg of oil treated.

Precise control of the filtration temperature, to optimize the quality of the process and immediately slow down degradation phenomena, both enzymatic and oxidative.

Extremely easy unloading and cleaning operations, designed to reduce downtime and improve operational efficiency.

Simple and intuitive operation, through dedicated software and a user-friendly interface, for a quick and hassle-free operating experience.

Reduced contact between oil and oxygen, thanks to the absence of dripping and the possibility of operating in a controlled atmosphere with nitrogen, preserving freshness and quality.

No contamination between cycles, which guarantees maximum product integrity at every stage.

Focus

1

THE SOFTWARE

Filtration cycle management software with data archiving to ensure complete process traceability.

The process is managed automatically, minimizing human error.

2

THE FILTER PRESS

The EXOOS filter press block is composed of a stainless steel structure, an integrated auger for unloading the adjuvants and a pack of filter plates which, thanks to a patented closing system, guarantees the absence of drips while maintaining a compact design.

3

HEAT EXCHANGE

A special feature of the filter is an integrated heat exchange system that allows optimal management of the filtration temperature (18–20 °C), heating or cooling the oil as needed.

This allows us to obtain a high-quality filtered oil even from freshly extracted oils.

The system can also operate in “heat exchange only” mode, without filtering.

Contact us for more details on our solutions

Mandatory fields*