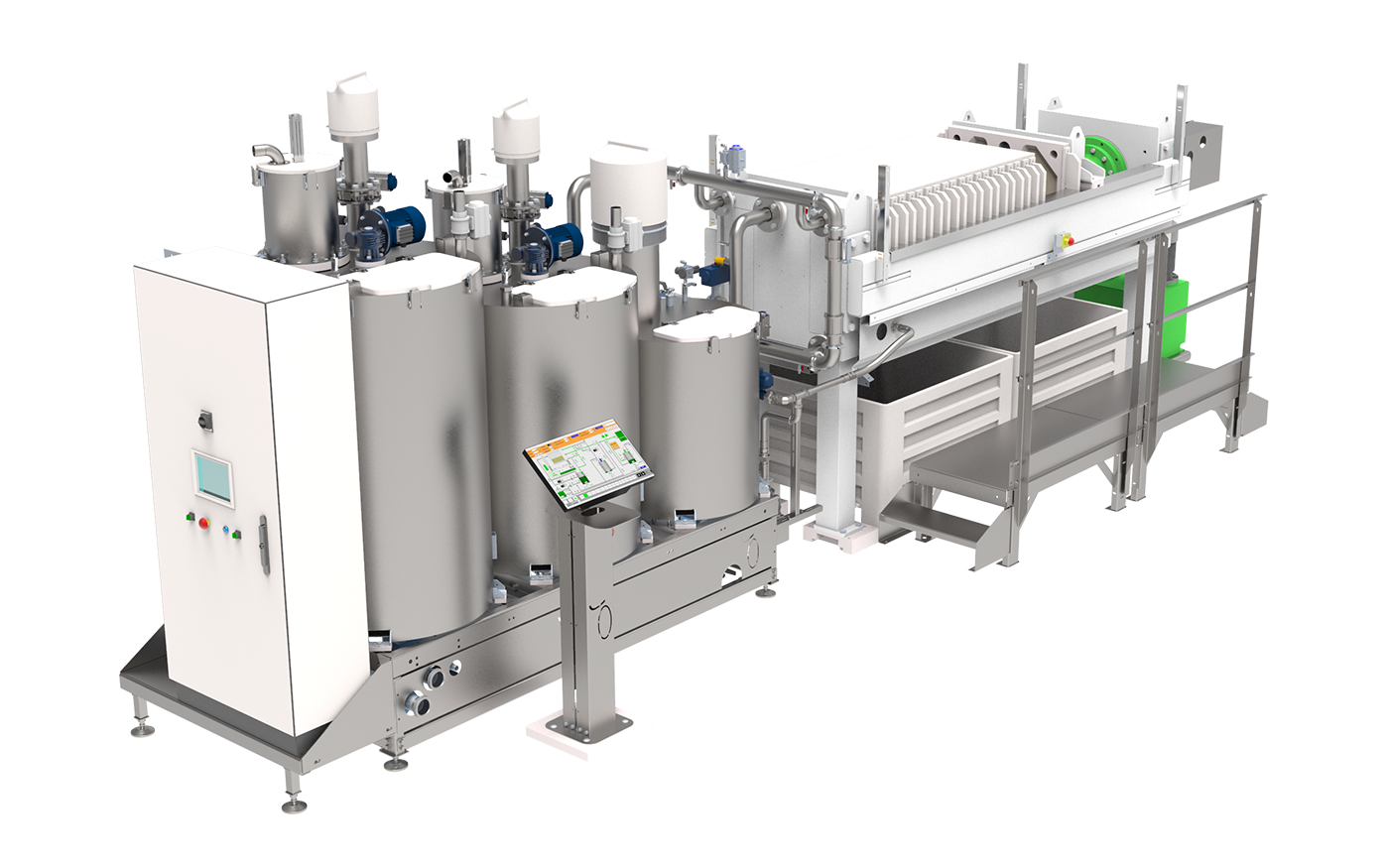

HIGH PERFORMANCE FILTRATION SYSTEM

Ideal for large mills and oil mills dedicated to high-quality production, with dimensions suitable for more complex processes.

or download the brochure

The Exoos filter press range was born from Italprogetti's desire to offer a filtration solution that combines high quality and minimizing losses.

Exoos' management and monitoring systems also make it an extremely efficient and easy-to-use machine. EXOOS filtration systems are designed to easily and effectively process even very difficult-to-filter olive oils (e.g., Greek olive oils), producing, in a single step, a high-quality filtered extra virgin olive oil, ready for bottling or final storage.

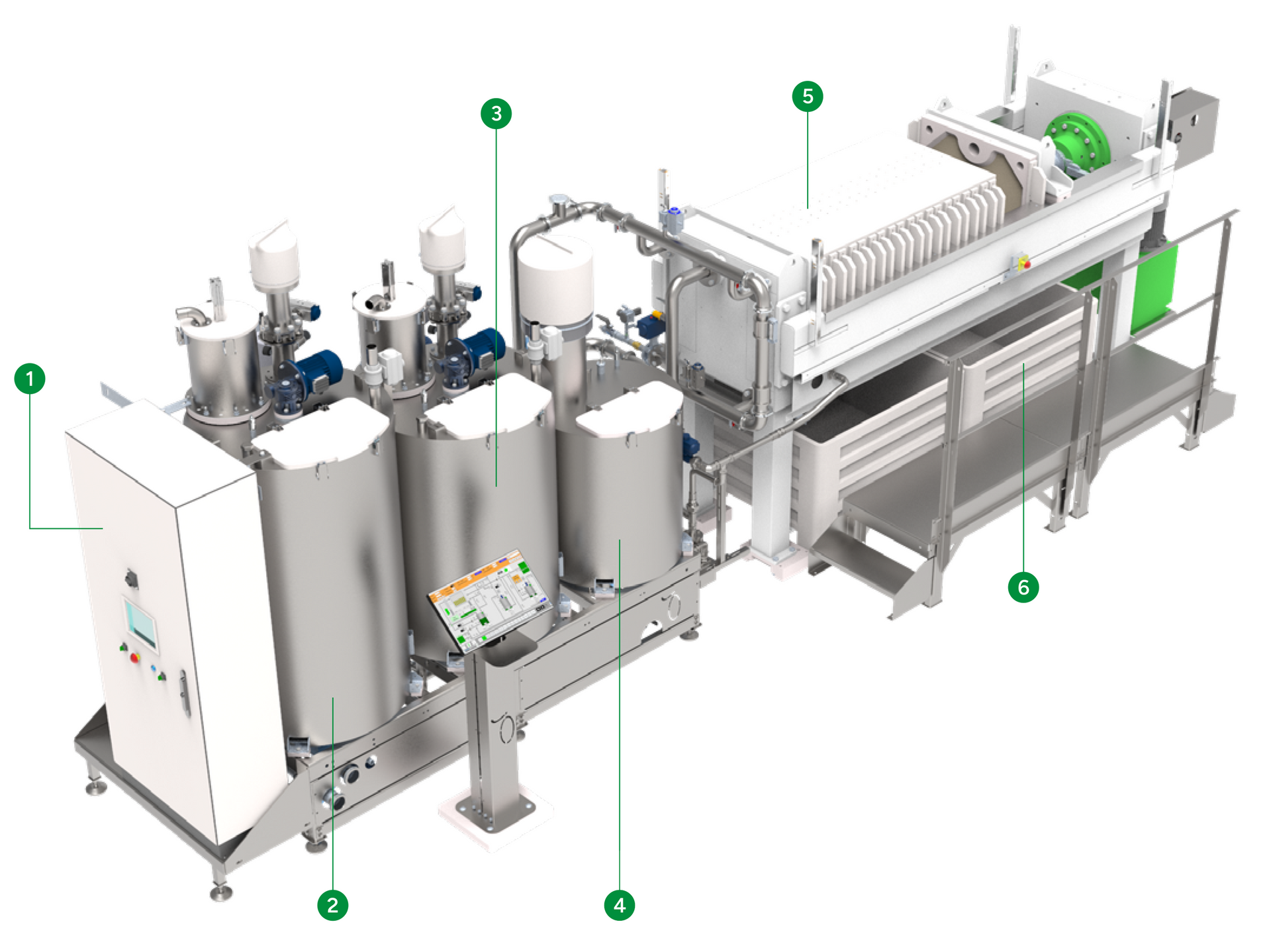

1

CONTROL PANEL WITH PLC AND TOUCH SCREEN

2

SLURRY TANK

3

PRECOAT TANK

4

FILTERED OIL TANK

5

FILTER PRESS WITH JOINT PLATE CHAMBER

6

COLLECTION OF EXHAUSTED ADJUVANTS

Some of the main advantages

The Exoos range of filter presses offers advanced and compact filtration solutions, combining efficiency and automation with quality and cleanliness in a single system.

Roughing and polishing in a single step, even with difficult oils and without the need for preliminary decantation.

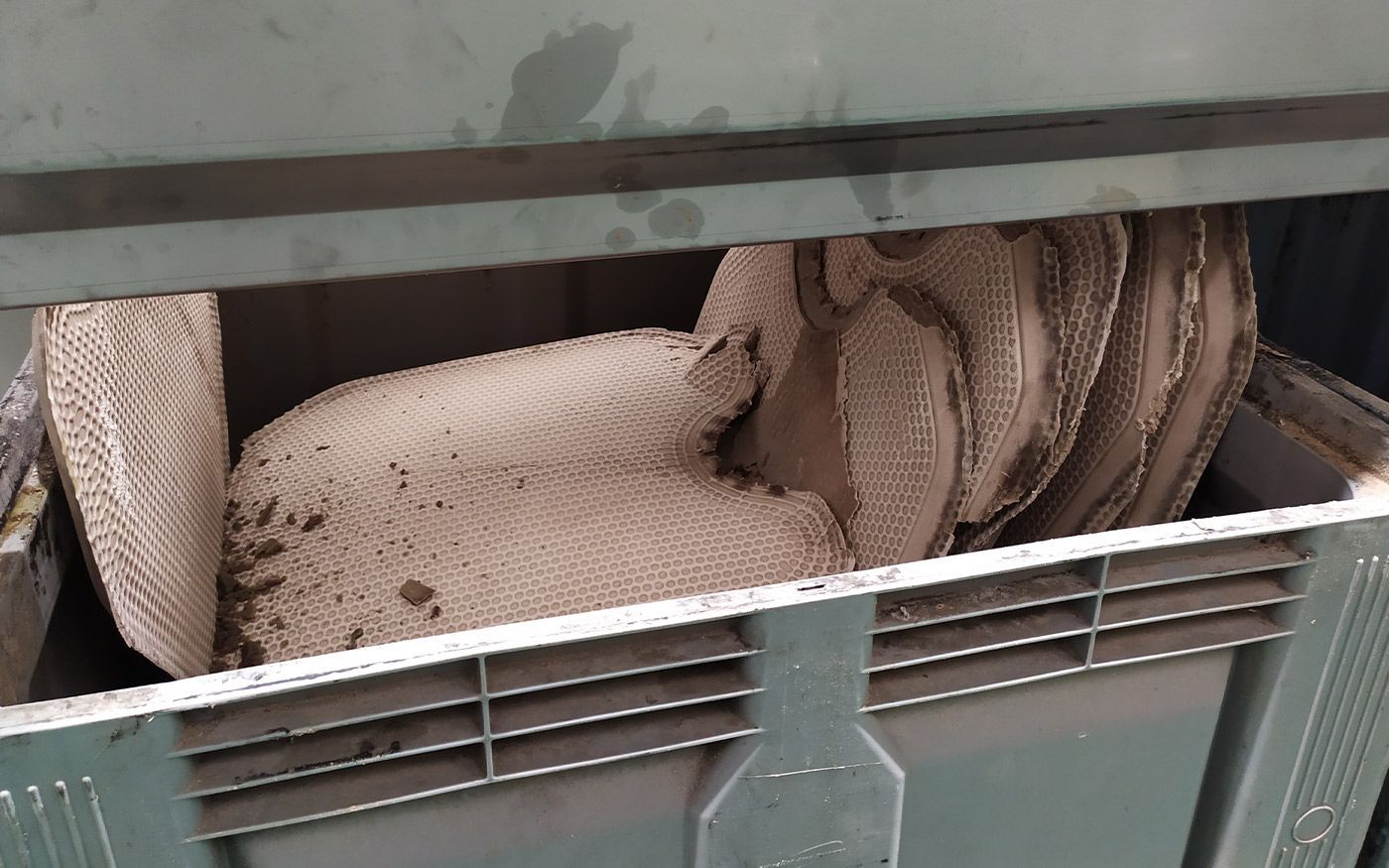

Exhausted, dry and compact panels (oil loss less than 1 kg for each ton filtered).

Software-based operation: minimal operator presence and the possibility of remote supervision.

Automatic adjuvant dosing.

Start&Stop without constraints.

Quick and easy unloading, cleaning and washing.

No dripping, even when unloading the panels.

Extremely quiet: noise level < 70 dBA.

Optional

1

PC SOFTWARE EXOOS PRO

ExoosPRO-Lite

The EXOOS system can be equipped with a touchscreen panel with SCADA software, which allows complete control of the system and data traceability.

Available features include: Remote supervision and management via PC, smartphone, or tablet Recording and archiving of data relating to filtered oils and the parameters of each filtration cycle, to ensure maximum traceability Monitoring of the adjuvants used during the process.

ExoosPRO-Full

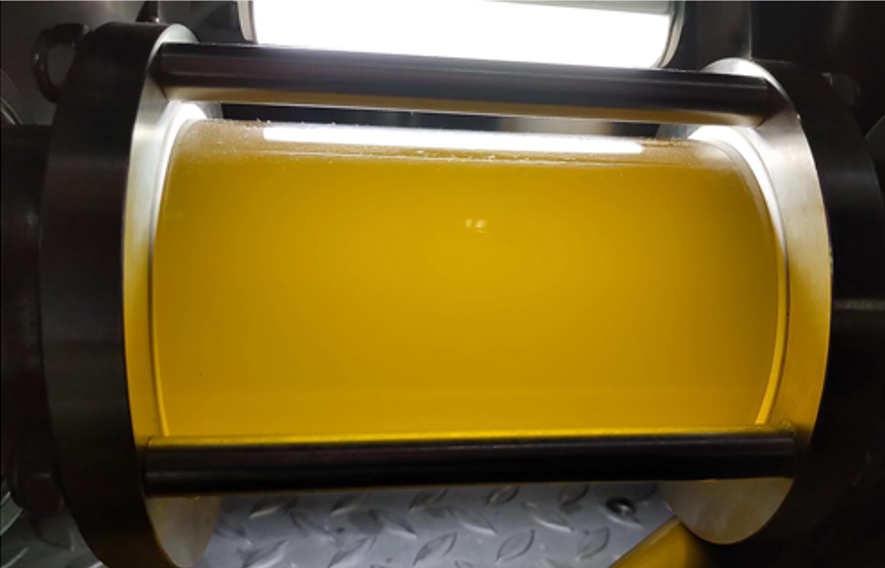

For even more advanced automation, the EXOOS system can be equipped with AI-based turbidity control. A camera captures images of the filtered oil, which are analyzed by the software.

EXOOSpro full: the system recognizes the turbidity level in real time and sends to the storage tanks only the oil that complies with the parameters determined by the Artificial Intelligence software, or set by the operator.

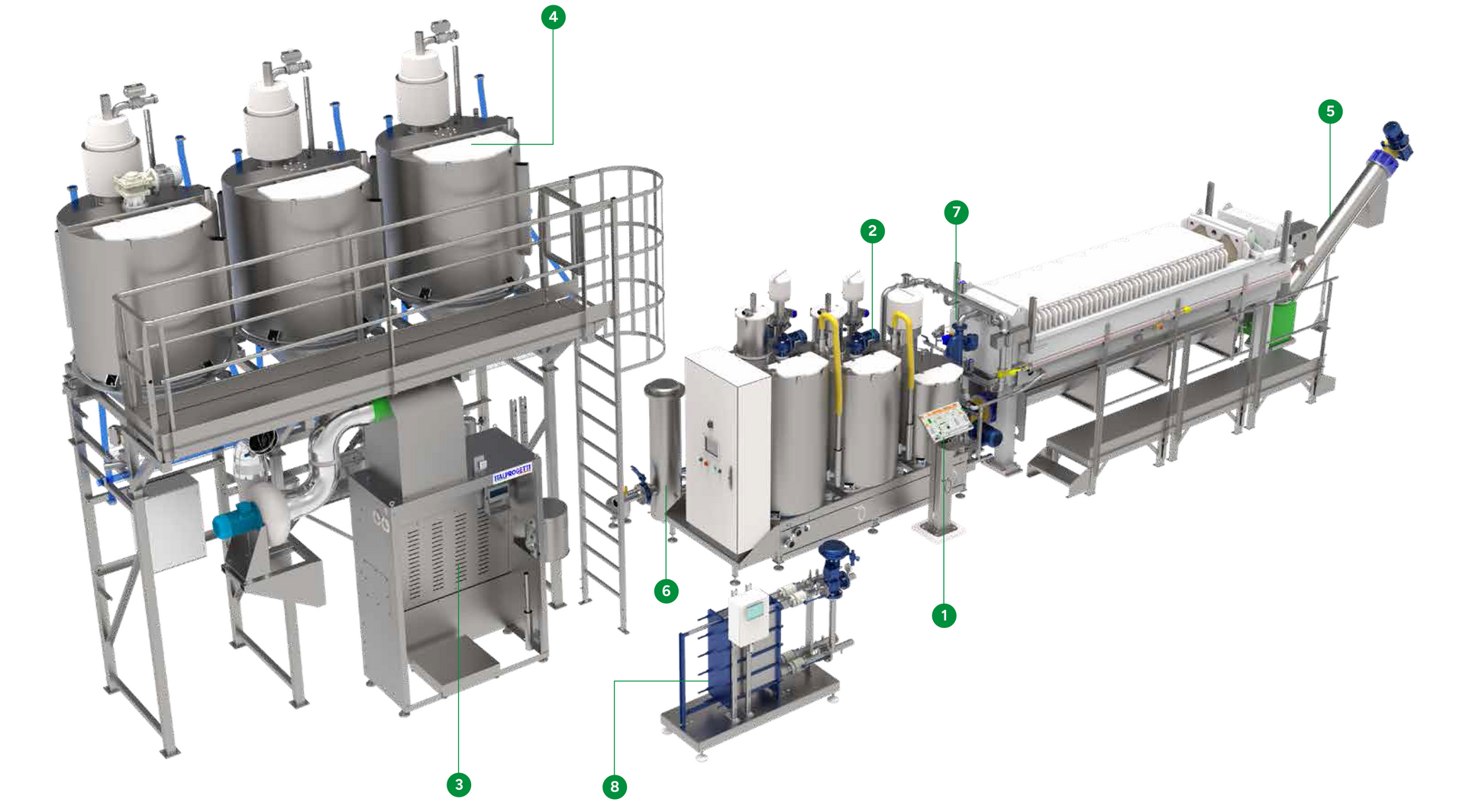

2

PNEUMATIC LOADING ADJUVANTS

The adjuvants are loaded into the tanks by means of a pneumatic suction system: the operator simply has to insert a cannula into the bag, thus speeding up the loading operation.

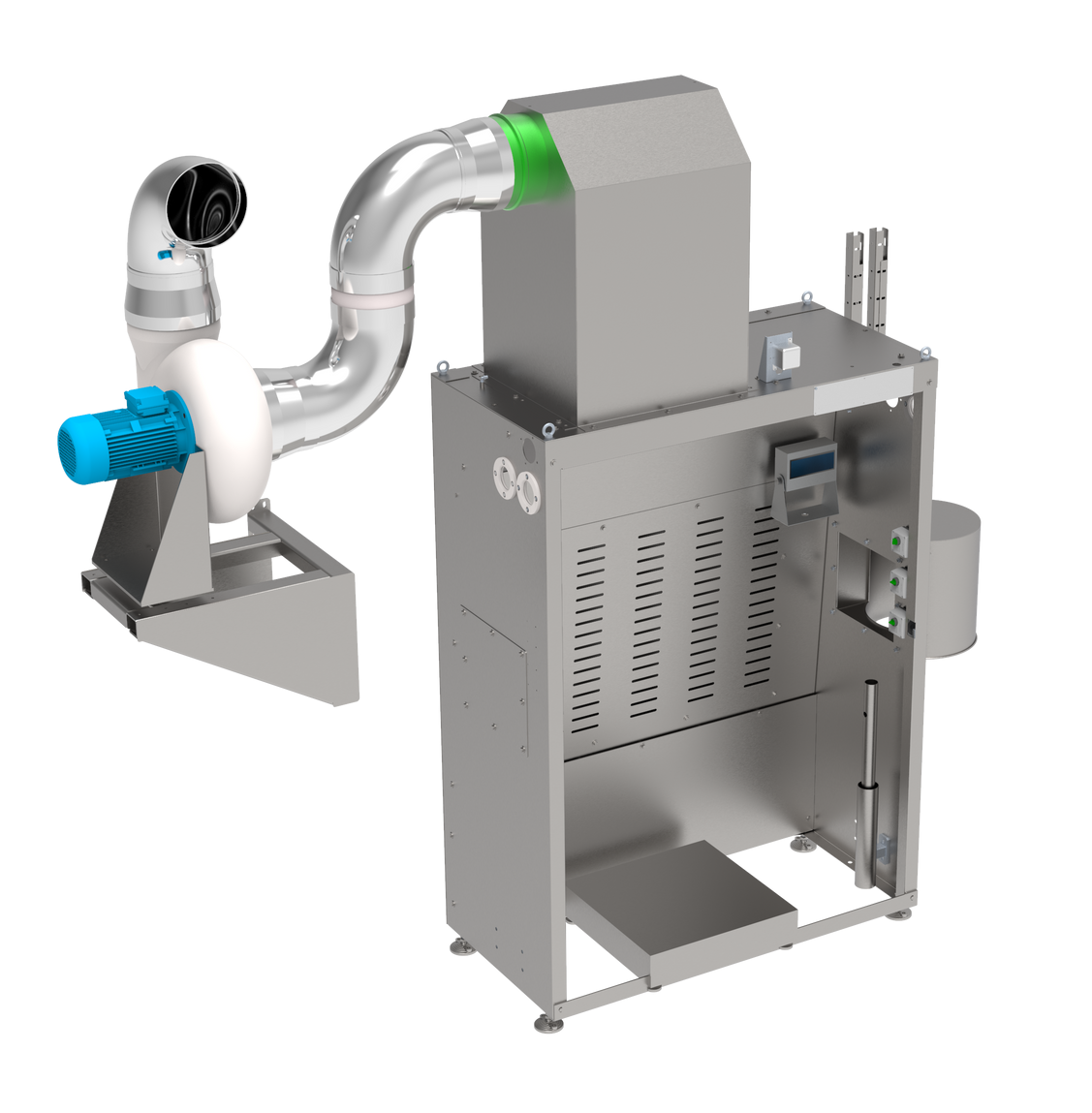

3

SUCTION CABIN

The processing aid extraction system can be equipped with a station comprising a fume hood, scale, and screen. The fume hood creates a slight vacuum in the loading area, eliminating the dispersion of processing aids into the work environment. The scale allows for quick and accurate weighing of processing aids during loading.

4

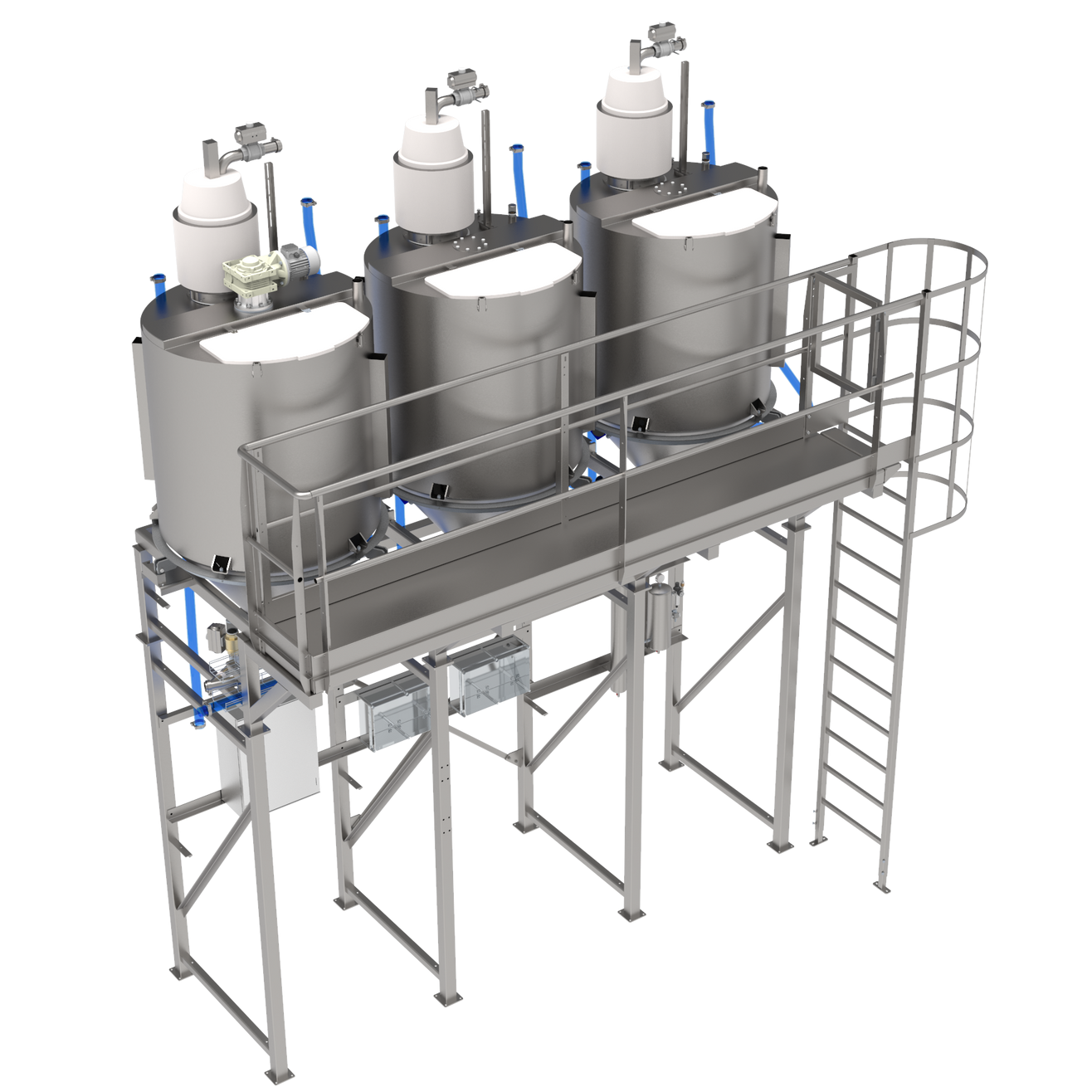

STORAGE OF ADJUVANTS IN SILOS WITH AUTOMATIC LOADING

The adjuvants are stored in silos complete with automatic weighing and loading systems. These silos have a much greater capacity than standard bags, allowing for fewer loading operations.

5

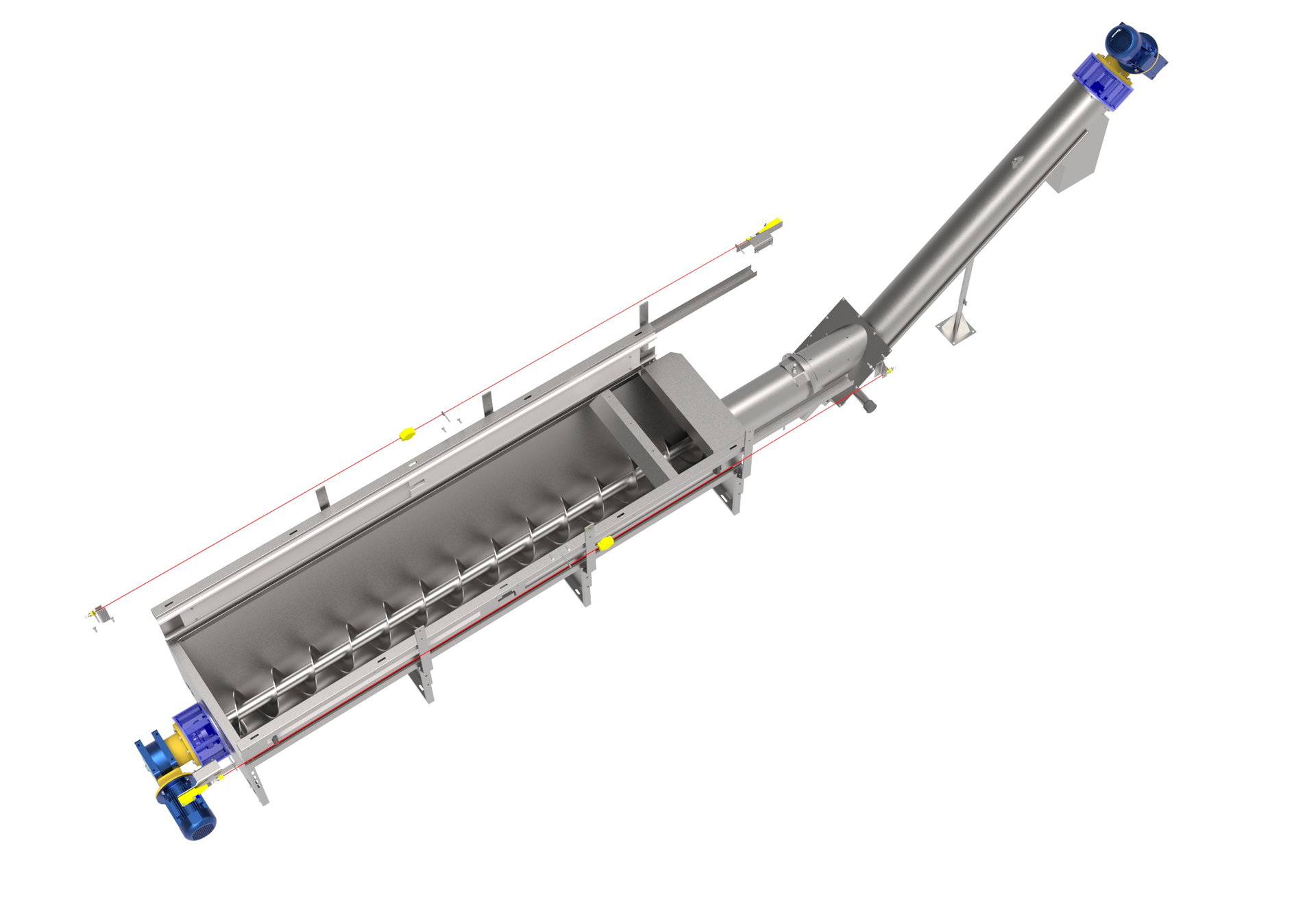

DISCHARGE AND COLLECTION SCREW

The used panels are collected in a hopper equipped with an auger, which allows them to be moved and unloaded into an external bin.

6

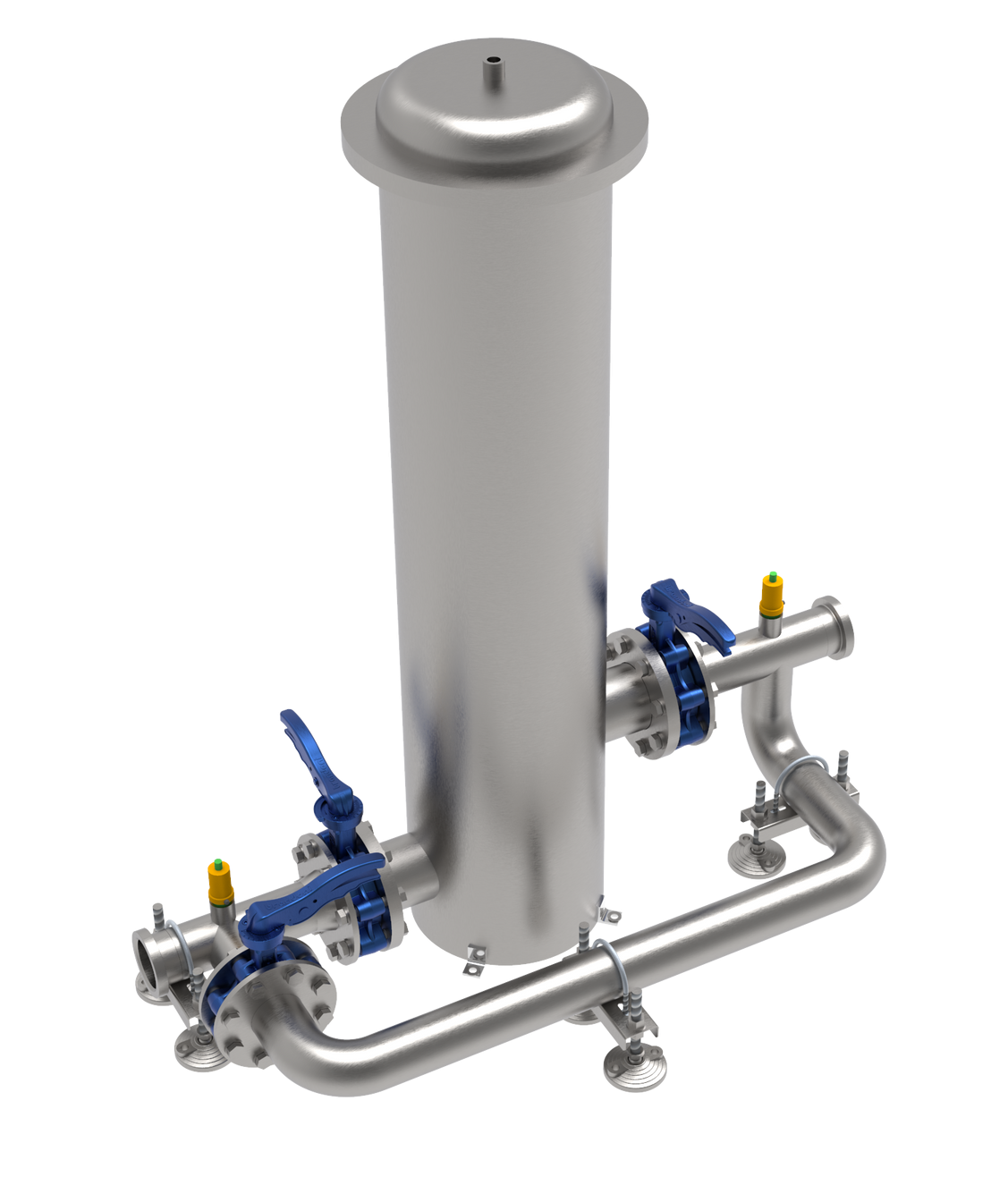

SAFETY FILTER

The safety filter offers additional protection, should it be necessary to intercept any solid particles in the event of a rare breakage of a filter cloth.

It is particularly useful when Exoos is connected directly to bottling plants or to prevent contamination of pipes and tanks.

7

FLOW METER

The integration of the Coriolis mass flow meter allows for extremely precise detection of the filtered oil flow rate, improving process management and the traceability of each filtration cycle.

8

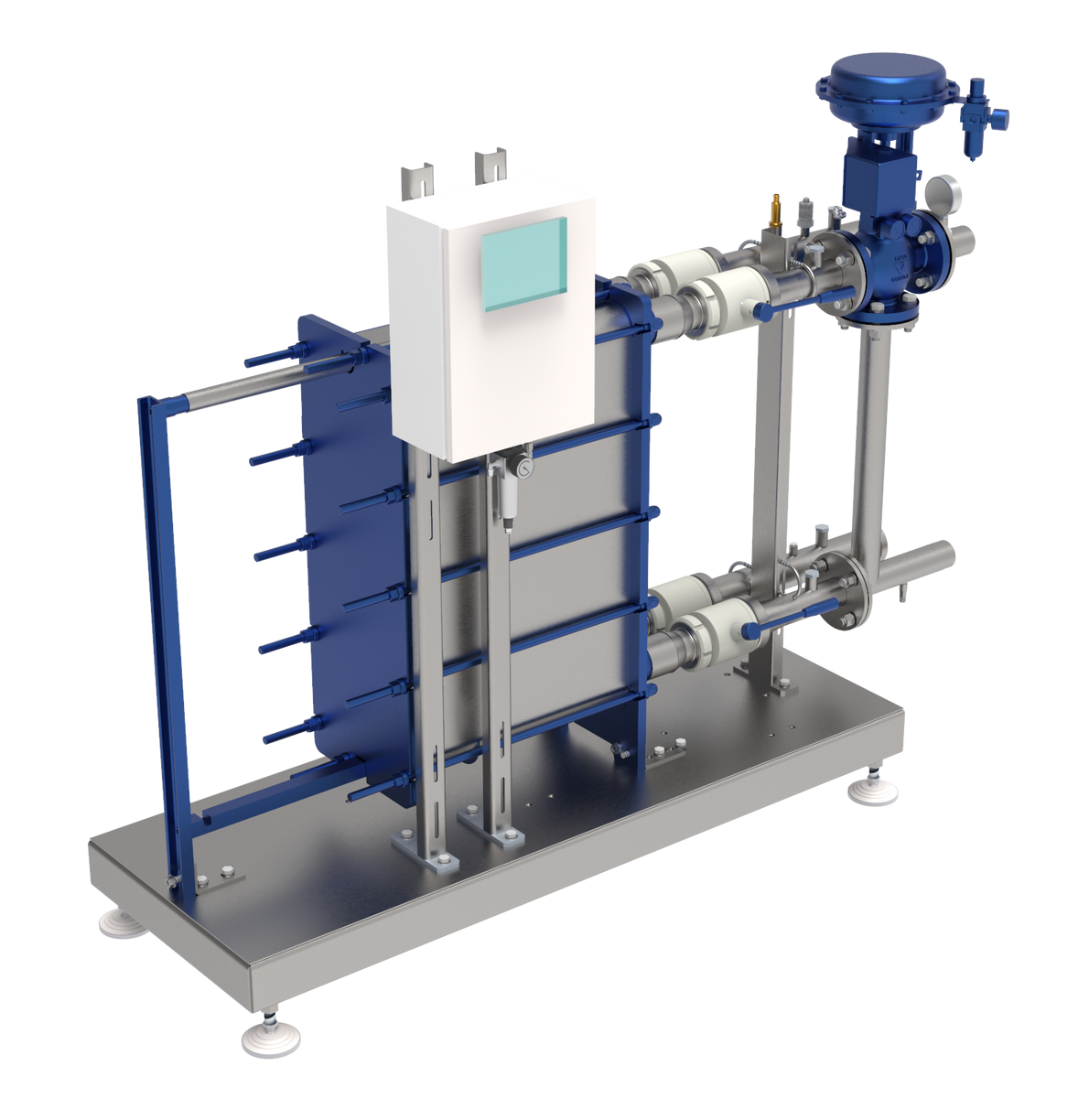

HEAT EXCHANGER

Depending on the needs, the oil is cooled or heated before being filtered. The process is automatically controlled by a dedicated PLC.

This allows the Exoos filter to operate in the optimal range of 18-20º C and to filter simply and effectively, guaranteeing a high-quality extra virgin olive oil in a single step, ready for bottling or final storage.

Contact us for more details on our solutions

Mandatory fields*